Source: AMF Additive Manufacturing Frontiers

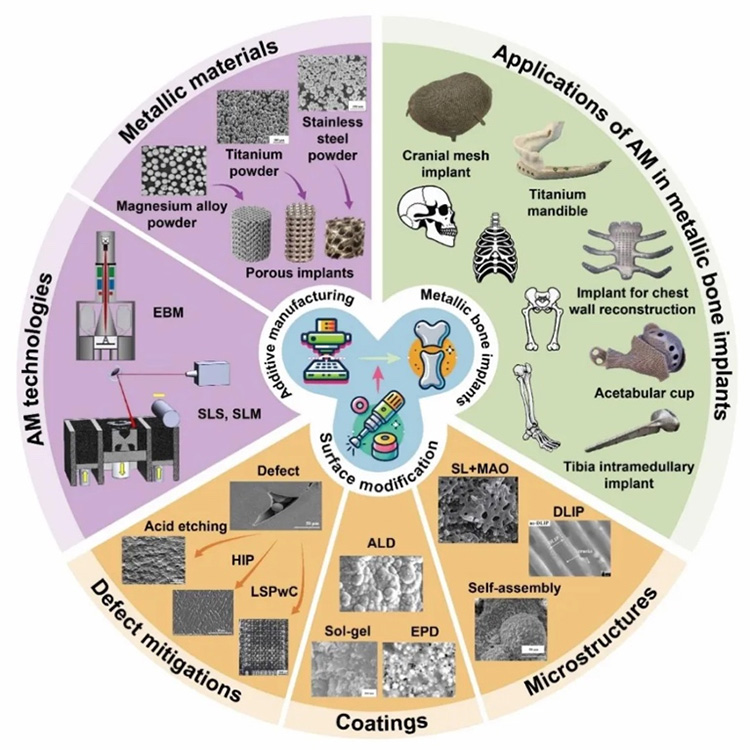

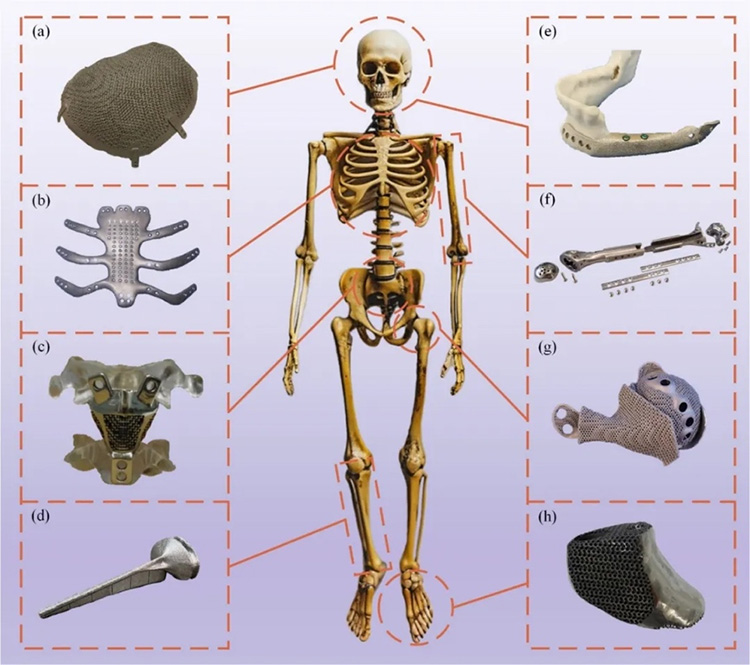

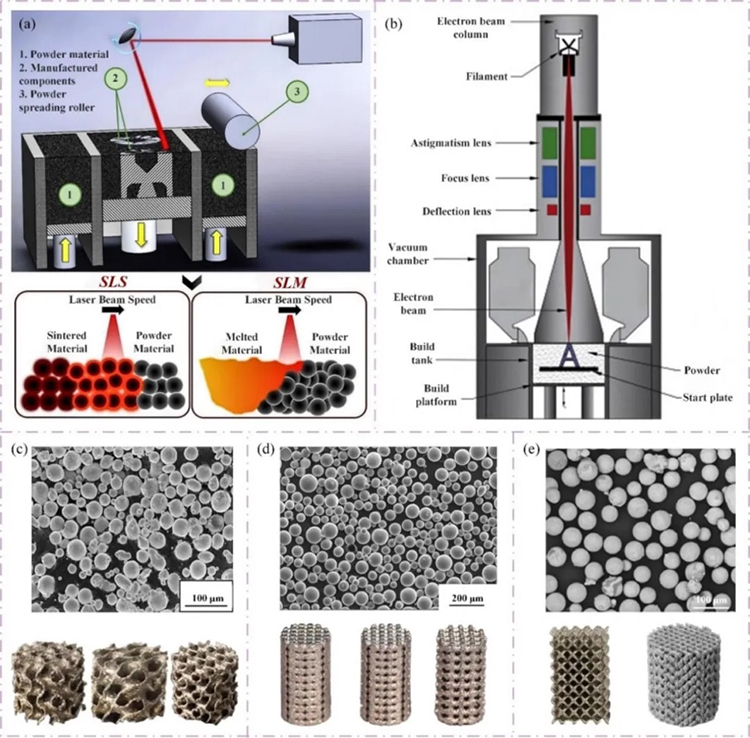

Surface modification technology is crucial for improving the mechanical properties and biocompatibility of the bone-implant interface. Through additive manufacturing (AM) technologies such as powder bed fusion, metal biomaterials like stainless steel, titanium and degradable alloys can be used to manufacture implants suitable for craniofacial, trunk and limb bone reconstruction. Subsequent sandblasting and chemical treatments are often used to improve the surface properties of implants. Functional coatings and micro-nano structures not only enhance the mechanical and biological interactions between implants and bone tissue but also help control drug release and enhance antibacterial performance.

Research difficulties or bottlenecks

The main difficulties include how to effectively eliminate the inherent defects generated during the AM process, such as unmelted powder, microcracks and high surface roughness. How to ensure uniformity and long-term stability in the coating aspect, and how to achieve a strong bond between the coating and the metal substrate without sacrificing mechanical properties. In addition, how can the additive manufacturing of degradable metals achieve better results by adjusting process parameters, and the matching of degradation rate and bone tissue healing rate.

Outlook

The combination of surface modification technology and AM technology is crucial for enhancing the biocompatibility, osteointegration potential and anti-infection ability of implants. Common surface modification strategies include mechanical and chemical interventions, as well as advanced methods such as laser surface treatment and sol-gel coatings. However, the long-term stability and uniformity of the coating are challenges, which affect the effectiveness and biocompatibility of the implant. Future research should develop new coating materials and application technologies to ensure long-term stability and uniformity in the context of personalized medicine. The application of emerging laser technology in creating micro - and nano-scale surface textures can significantly influence cell behavior, enhance bone integration and anti-infection capabilities. With the in-depth understanding of the interaction among implant materials, surface characteristics and biological reactions, the role of surface engineering in optimizing the performance of AM bone implants is becoming increasingly important.

Cite papers

Jianhui Li, Haitao Fan, Hui Li, Licheng Hua, Jianke Du, Yong He, Yuan Jin. Recent Advancements in the Surface Modification of Additively Manufactured Metallic Bone Implants. Additive Manufacturing Frontiers, Volume 4, Issue 1, 2025, 200195.

https://doi.org/10.1016/j.amf.2025.200195.

The article links: https://www.sciencedirect.com/sc... i/S295043172500005X

About the team

He Yong (Corresponding author), a Qiu Shi Distinguished Professor at Zhejiang University, recipient of the National Science Fund for Distinguished Young Scholars, deputy director of the National Key Laboratory of Fluid Power Basic Components and Mechatronic Systems, associate editor of the journal Bio-Design Manufacturing, and editorial board member of the journal Biofabrication. Engaged in research on additive manufacturing (3D printing), biomanumanufacturing and other fields, he/she has presided over six projects funded by the National Natural Science Foundation of China, including the National Science Fund for Distinguished Young Scholars, Key Projects, Outstanding Young Scholars and Key Projects of the Joint Fund. He/She has published two monographs on bio-3D printing and obtained over 50 authorized invention patents. More than 100 SCI papers have been published in issues such as Science Translational Medicine, Nature Reviews Bioengineering, Nature communications, and Science Advances. The H-index is 66 and the paper has been cited over 13,000 times. He serves as the deputy director of the Advanced Manufacturing Branch of the Chinese Society for Biomaterials and a standing committee member of the Biomanufacturing Branch of the Chinese Mechanical Engineering Society. He created the EFL brand (Engineering for life) and is committed to interdisciplinary research and technology transfer in medicine and engineering.

Jin Yu 'an (co-corresponding author), a professor and doctoral supervisor at Ningbo University, has long been dedicated to the research of 3D printed multi-functional structures and devices. As the first author or corresponding author, 38 SCI/ EI-indexed papers have been published, including 18 TOP journal papers and 2 ESI highly cited/hot papers. The total citation count of the papers has reached over 2,500 times, and the H-index is 26. He has presided over 2 projects funded by the National Natural Science Foundation of China, 2 projects funded by the Natural Science Foundation of Zhejiang Province, and the Ningbo Youth Science and Technology Leading Talent Project. He has been granted 19 national invention patents.

Research direction of the team

3D printed multi-functional structures and devices

The team has published articles in recent years

[1] Qunyao Zhang, Yuan Jin*, Yong He, et al. Hierarchically structured hollow PVDF nanofibers for flexible piezoelectric sensor, Chemical Engineering Journal, 2024(498): 155661.

[2] Yanru Mu, Yuan Jin*, et al. Mechanical performance of interpenetrating phase composites with multi-sheet lattice structures. International Journal of Mechanical Sciences, 2024, 276: 109369.

[3] Jianhui Li, Yong He*, Yuan Jin*,et al. Bone implants with triply periodic minimal surface architectures: design, fabrication, and biological performance, Bio-Design and Manufacturing, 2024.

[4] Yanru Mu, Yuan Jin*, et al. Mechanical properties of a novel hierarchical cellular structure architectured with minimal surfaces and Voronoi-tessellation, Composite Structures, 2023(325):117160.

[5] Weiwei Wang, Yuan Jin*, et al. A novel tubular structure with negative Poisson's ratio based on gyroid-type triply periodic minimal surfaces, Virtual and physical prototyping, 2023(18):e2203701.